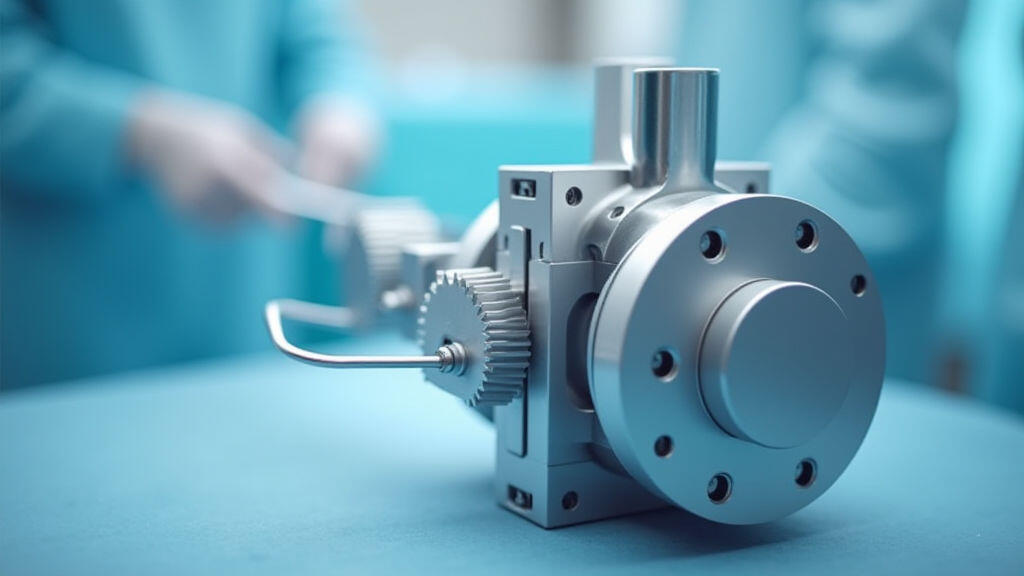

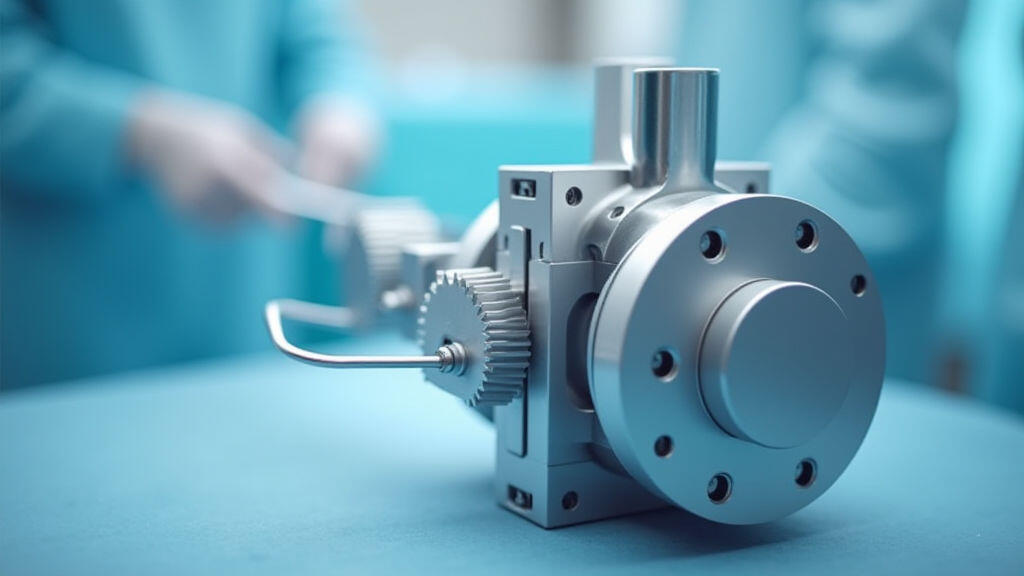

The medical equipment industry demands unwavering reliability, precision, and safety. From sophisticated imaging systems to life-supporting devices, the performance of these machines directly impacts patient outcomes. At the heart of many medical devices lies the gear reducer – a critical component responsible for translating motor speed and torque into the precise motion required for functionality. Selecting the right gear reducer isn't just an engineering decision; it’s a crucial factor in ensuring patient safety, equipment longevity, and regulatory compliance. This article shares practical experience and insights, drawing on industry best practices, to guide engineers and decision-makers in choosing gear reducers for medical equipment applications.

Unlike industrial applications, medical equipment faces stringent performance requirements. These aren't simply about power transmission; they encompass:

These demands necessitate a careful and methodical approach to gear reducer selection.

Choosing the correct gear reducer isn't a one-size-fits-all process. Here's a breakdown of the key factors to consider:

1. Torque and Speed Requirements: This is the fundamental starting point. Accurately calculate the required input and output torque, along with the desired output speed. Consider peak loads and variations in operating conditions. Tools like torque analyzers and simulation software can be invaluable.

2. Gear Type: Several gear types offer distinct advantages.

For medical equipment, helical and worm gears are frequently preferred due to their higher efficiency, lower noise, and smoother operation.

3. Efficiency: Gear reducer efficiency directly impacts power consumption and heat generation. Higher efficiency reduces operating costs and minimizes the risk of overheating. Look for gear reducers with high efficiency ratings (typically above 90%).

4. Size and Weight: Space constraints are often a critical factor in medical device design. Select a gear reducer that fits within the available space while meeting performance requirements. Weight is also important, particularly in portable or implantable devices.

5. Materials: The materials used in the gear reducer significantly impact its performance and lifespan. Stainless steel is commonly used in medical equipment due to its corrosion resistance and biocompatibility. Consider materials compatible with sterilization processes.

6. Noise and Vibration: Medical devices often operate in sensitive environments. Choose a gear reducer designed to minimize noise and vibration. Features like noise dampening materials and optimized gear geometry can help.

7. Safety Features: Reducers that incorporate safety features like overload protection and thermal protection are essential for preventing damage and ensuring patient safety.

8. Regulatory Compliance: Verify that the gear reducer complies with all relevant regulatory standards (FDA, CE, IEC). Obtain necessary certifications and documentation.

Our experience at MES-Drive has revealed several common challenges in gear reducer selection for medical equipment:

To address these challenges, MES-Drive provides:

The integration of Internet of Things (IoT) technology is revolutionizing medical equipment. Smart gear reducers, equipped with sensors and connectivity, offer unprecedented capabilities:

MES-Drive is actively developing smart gear reducer solutions for the medical industry, leveraging IoT technology to enhance reliability, safety, and efficiency.

Selecting the right gear reducer is a critical decision in the medical equipment field. It’s not just about power transmission; it’s about ensuring patient safety, equipment reliability, and regulatory compliance. By carefully considering torque and speed requirements, gear type, efficiency, materials, noise levels, and safety features, engineers can choose gear reducers that meet the unique demands of their applications.

With the emergence of smart gear reducers and IoT technology, the future of medical equipment is poised for even greater innovation. The ability to monitor performance remotely, predict failures, and optimize efficiency will further enhance the reliability and safety of critical medical devices. As the healthcare industry continues to evolve, MES-Drive is committed to providing cutting-edge gear reducer solutions that enable the next generation of medical technology. The increasing prevalence of remote patient monitoring and telehealth solutions will further drive demand for reliable, compact, and intelligent gear reducers capable of operating continuously and providing accurate, consistent motion.

Leave A Reply

Your email address will not be published. Required fiels are marked